Excavator Safety & Productivity

Still not sure what solution you require?

| Function | XW1 | XW2 | XW3 | XW4 | XW5 |

|---|---|---|---|---|---|

| Height Limitation | * | O | * | * | |

| Slew Limitation 'Angular' | * | * | |||

| Slew Limitation 'Virtual wall' | O | * | |||

| Rated Capacity Indicator 'RCi' | O | O | |||

| Rated Capacity Limiter 'RCL' | * | * | |||

| 'Creep Control' - third party connectivity | O | ||||

| 'IoT' Connected Site - telematics | O | O | O | O | O |

| Network Rail Approved | non-railborne plant | * | * | * | * | * |

Key '*' Standard 'O' Optional

XWSeries XW1 | XW2 | XW3 | XW4 | XW5 | XWTele

Have Network Rail Approval for operation on non-railborne (construction) plant and equipment used on or near Network Rail Infrastructure.

Height Limiters

Monitors and controls the working height of the machine. This allows the operator or supervisor to set a Height Limit suitable for the site conditions, thus increasing site Safety and Productivity as the machine can be operated in the confidence that the equipment will be unable to breach the ceiling set.

Rated Capacity Indicators 'RCi'

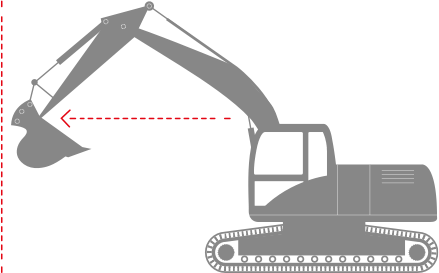

An excavator is designed for digging but due to their flexibility they are more often than not used for lifting. This means that the excavator designed for digging is now being used as a crane. If lifting more than 1 tonne the operator is required to see on an in cab display the Load, Height and Radius ensuring regulatory compliance. Your excavator can become a crane once it has an RCi solution installed (check valves and other requirements would also need to be met).

Rated Capacity Indicator is included in the following solutions

XW2

XW5

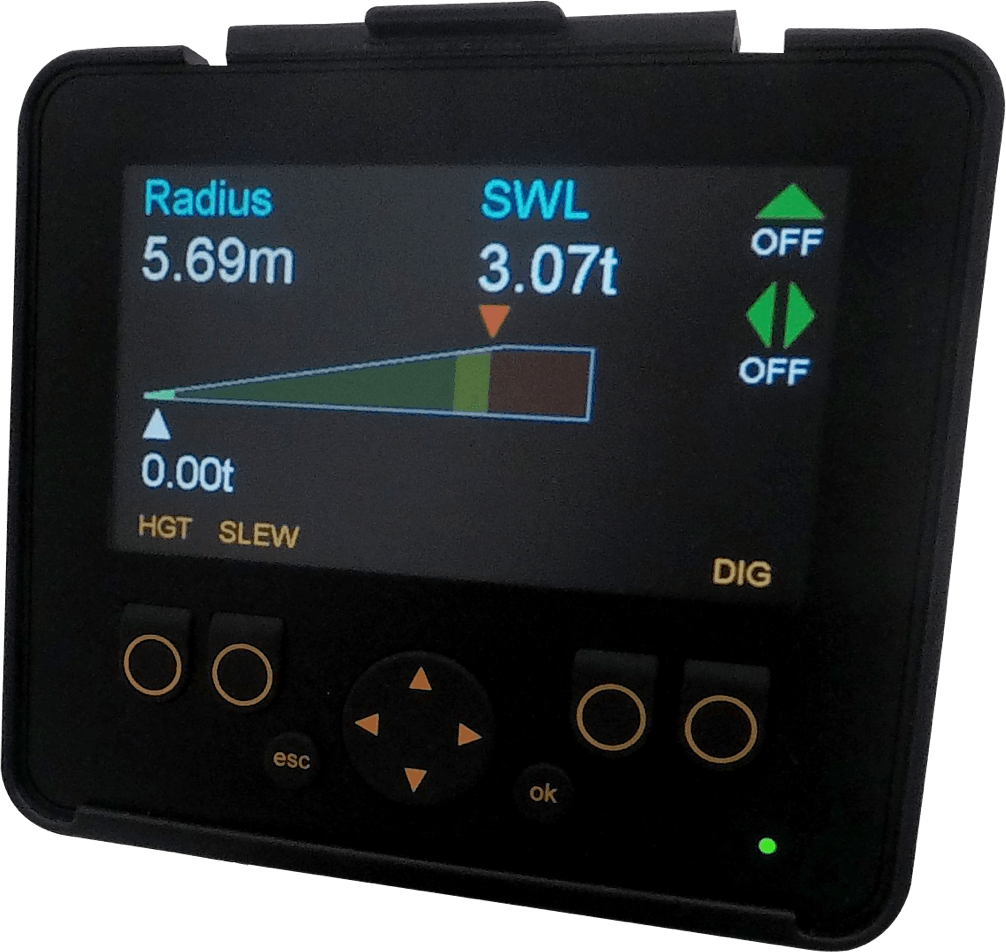

Rated Capacity Indicator 'RCi'

This solution will monitor the lifting operation.

Rated Capacity Limiter 'RCL'

This solution will not only monitor but control the lifting operation, maximising the lift capacity well not allowing the machine to exceed it's lift capabilities.

Height Limitation comes as standard with 'RCL.'

Slew Limiters

There are two types of Slew Limitation.

Simple Angular Slew whereby the Slew left and Slew right of the machine are monitored and controlled.

Virtual Wall is a more complex Slew Limitation whereby both the slew of the machine and extension are monitored and controlled.

Why the XW series

The XW series of solutions reside on a common platform making each product easily upgradable with information presented to the operator on a clear TFT in cab display. All major components are sourced from quality manufactures whom have been delivering durable products into harsh environments for decades. The angle sensors employed are of the latest design, their compact stainless-steel construction contains a solid state triaxial accelerometer with gyro compensation. Combine this with the XW series firmware and you have the incomparable solution. In addition to this moving forward the XW series will be able to integrate with anti-collision systems, RFID Proximity Warning Systems, Camera awareness systems, 3D machine control and telematics. The control element is managed with proportional soft-stop hydraulic valves providing safe, accurate performance without detriment to the equipment to which it is installed. Operation is fail safe as you would expect from a safety solution.

XW1 is designed for monitoring and controlling the movement of any articulating equipment. The system measures position via the use of angle sensors to the latest design, their compact stainless-steel construction contains a solid state triaxial accelerometer with gyro compensation. These sensors guide the operator to stay within a user defined working envelope. The basic system monitors vertical height and dig depth with a fully featured variant available monitoring the machine’s vertical 2D envelope (height, reach, cab protection, depth); fully describing the machine’s working envelope. Optional control on hydraulic motion can be installed to automatically control movement on reaching user-set limits.

The operator will benefit from the XW series easy to use Man Machine Interface 'MMI' integrated within the foundation of the series.

The XWTele and XWFork are part of a suite of safety products from the XW series that have been designed to couple clarity and simplicity with accuracy and reliability while complying with all the current industry standards. XWTele is specifically designed for telehandlers, XWFork for industrial and rough terrain forklift trucks. Height limitation is controlled using outputs for boom up and tele extend on telehandlers, or forks up on forklift trucks. A height limit can be either manually keyed in or set automatically by positioning the machines equipment at the required height. Setting limits is simple, quick and can be protected with an optional access key switch.

The operator will benefit from the XW series easy to use Man Machine Interface 'MMI' integrated within the foundation of the series.

Fully engineered for compatibility with all major manufacturers, the system maximises your machine’s productivity when lifting. Using XW2 ensures your construction equipment remains LOLER compliant whilst also enabling you to tender for work with larger major infrastructure projects and tier one contractors.

XW2 Brochure

XW2 is designed to ensure the safety of lifting operations. The system measures the load and guides the operator, ensuring the lift is performed safely and within the machine’s limits. A TFT in cab display, daylight viewable, allows operators to monitor the approach to these limits and input parameters required for the job. XW2 can optionally control hydraulic motion ensuring the machine is maintained within safe limits during lifting. Additionally the system can provide real time limitation of the machines working envelope (height, reach and depth) to avoid hazards during operation. The operator will benefit from the XW series easy to use Man Machine Interface 'MMI' integrated within the foundation of the series.

The XW3 is dedicated to Slew control, designed to work within user defined Slew left and Slew right limits. A 'V' shaped working area defined by the operator.

For more complex Slew limitation employ the XW4 Height and Slew limiter which includes virtual wall.

The operator will benefit from the XW series easy to use Man Machine Interface 'MMI' integrated within the foundation of the series.

XW4 is designed to control the movement of an excavator in all planes; vertical and horizontal providing full 3D envelope control. Offering multiple options for control, this system combines the slew sensing of XW3 with the 2D envelope, height and depth monitoring and control of XW1 in one integrated solution. As with the whole XW series this system comes with a TFT in cab display, daylight viewable and allows operators to monitor the approach to set limits and input parameters required for the site conditions allowing multiple configurations of the envelope to be described, monitored and controlled. Optional motion cuts on any hydraulic service are possible allowing both monitoring and control on the machine movement.

The operator will benefit from the XW series easy to use Man Machine Interface 'MMI' integrated within the foundation of the series.

Maximise asset performance and regulatory compliance in lifting and carrying operations with the XW series RCi and RCL monitoring and controlling load & 3D machine envelope.

XW5 combines all functions of the XW series. Combining real time load and position the system will maintain a safe load and stay within a defined envelope in both the horizontal and vertical plane. The carried load is displayed graphically to the operator and warnings are given on approach to the maximum Safe Working Load (SWL). As with the whole XW series this system comes with a TFT in cab display which shows the limits for slew and height and these can be set according to the operational or environmental requirements of the equipment to meet site conditions. This system fully complies with EN and UK LOLER requirements for safe load indicators and is type approved for operation in all EU countries. The system is set up for hydraulic control on all motions and, when combined with proportional hydraulic motion cut valves, will limit travel in any plane to the defined envelopes.

The operator will benefit from the XW series easy to use Man Machine Interface 'MMI' integrated within the foundation of the series.

On a standard mono machine how many motion cuts do I require?

| Function | Required No. | Boom up | Boom down | Dipper in | Dipper out | Slew left | Slew right |

|---|---|---|---|---|---|---|---|

| Height Limitation | 2 | * | * | ||||

| Slew Limitation 'Angular' | 2 | * | * | ||||

| Slew Limitation 'Virtual wall' | 6 | * | * | * | * | * | * |

| Rated Capacity Indicator 'RCi' | 0 | ||||||

| Rated Capacity Limiter 'RCL' | 4 | * | * | * | * |

XWSeries world first!

Introducing 'Creep Control'

Automatic safety control via third-party integration. Creep Control is the latest innovation for the XWSeries and can be initiated via a third-party system. This can be any approved third-party solution such as an RFID Proximity Warning System ‘PWS’ or camera solution with personnel awareness for example. During a detection ‘Creep Control’ activates and slows down the excavator, the operator remains in full control with full power but at a reduced speed so the ground operations can be protected, and work carried out within the slew area.

Once the ground worker leaves the area and the third-party awareness system sees that the danger has passed, the ‘Creep Control’ allows the machine to go back to a normal operating speed. All without any operator interaction supporting our #ClearMind #ClearView approach, all backed up with alerts and data from the telematics interface where installed.

XWSeries world first!

Introducing Telematics for 'RCi's, Height & Slew Limiters

If you own a fleet of machines, it's likely they are from several different manufactures meaning you need to log onto each OEM’s IoT portal to view that manufactures machines within your fleet.

With the XWSeries Safety and Productivity telematics you could be viewing all your machines from a single web portal. You would have the ability, but not limited to; view the assets location it’s activities; utilisation, limits set, current Load-On-Hook etc With telematics comes data logging, accessible from your desktop or mobile device with data securely held in the cloud so no need for a costly visit to site to remove the data from the system and the processing of that data, it's all to hand with a couple easy clicks of the mouse.